In the realm of manufacturing, precision is paramount. Whether you’re producing intricate automotive components or delicate electronic parts, ensuring accuracy is not just a preference but a necessity. This is where checking fixtures step in as indispensable tools, offering a reliable means to verify the dimensional accuracy and quality of manufactured parts.

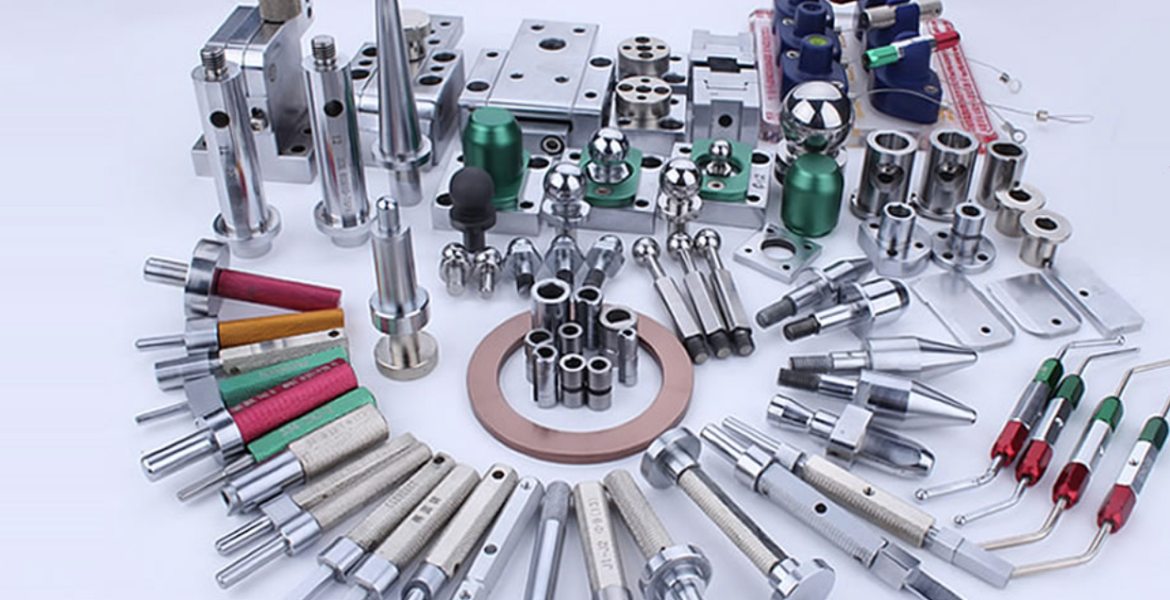

However, the effectiveness of a checking fixture doesn’t solely depend on its design and construction. Equally crucial are the accessories that complement these fixtures, enhancing their functionality, versatility, and overall performance. In this blog post, we’ll delve into the world of checking fixture accessories, exploring their significance and the diverse range of options available.

Understanding the Role of Checking Fixture Accessories

Before delving into specific accessories, let’s grasp the fundamental role they play in the context of checking fixtures. Essentially, these accessories serve to augment the capabilities of the fixture itself, catering to diverse requirements across various manufacturing processes. They enable finer adjustments, facilitate efficient part positioning, and contribute to overall productivity. Whether it’s improving accessibility, increasing stability, or accommodating different part geometries, the right accessories can make a substantial difference in the effectiveness of a checking fixture.

Exploring Common Checking Fixture Accessories

- Clamps and Fasteners: These are essential for securely holding the part in place during inspection. Depending on the geometry and material of the part, various types of clamps and fasteners such as toggle clamps, pneumatic clamps, and magnetic clamps are utilized to ensure stability and repeatability.

- Locating Pins and Bushings: Precise positioning of the part within the fixture is critical for accurate measurement. Locating pins and bushings help achieve this by providing reference points for aligning the part consistently.

- Adjustable Supports and Rests: Not all parts have uniform shapes or sizes. Adjustable supports and rests allow for accommodating parts of different dimensions, ensuring optimal contact and stability during inspection.

- Surface Plates and Mounting Bases: A flat, stable surface is essential for the accurate functioning of a checking fixture. Surface plates and mounting bases provide this foundation, minimizing errors caused by uneven surfaces.

- Modular Components: Modular accessories offer flexibility by allowing the fixture to be reconfigured or adapted for different parts or inspection requirements. This modularity enhances versatility and cost-effectiveness in a dynamic manufacturing environment.

- Datum Systems: Datum systems establish the primary reference points for measuring the part’s dimensions and tolerances accurately. They comprise features such as datum pins, surfaces, and holes, crucial for alignment and establishing coordinate systems.

- Measurement Devices: While not technically part of the fixture itself, integrating measurement devices such as dial indicators, probes, or laser sensors can enhance the functionality of the fixture, enabling in-situ measurement and data collection.

The Impact of Quality Checking Fixture Accessories

Investing in high-quality checking fixture accessories can yield several benefits for manufacturers:

- Improved Accuracy: Precision-made accessories contribute to the overall accuracy of the inspection process, ensuring reliable measurement results.

- Enhanced Efficiency: Streamlined setups and quicker adjustments facilitated by accessories translate to time savings and increased productivity on the production floor.

- Greater Versatility: With a diverse array of accessories at their disposal, manufacturers can adapt fixtures to accommodate varying part geometries and inspection requirements without extensive retooling.

- Reduced Rework: Accurate measurements from well-equipped fixtures reduce the likelihood of defective parts escaping detection, minimizing rework and associated costs.

In conclusion, while the checking fixture itself forms the backbone of dimensional inspection processes, it’s the accessories that truly elevate its effectiveness. From clamps and pins to modular components and measurement devices, each accessory plays a crucial role in ensuring precise, efficient, and adaptable inspection procedures. By investing in quality checking fixture accessories, manufacturers can uphold the highest standards of quality control, ultimately leading to enhanced product quality and customer satisfaction.